Cloth tapes

Cloth tapes Specification

- Shelf Life

- 12 Months

- Length

- 50-60 Millimeter (mm)

- Adhesive Side

- Single Side

- Material

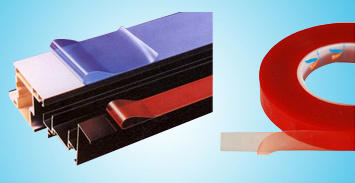

- acrylic foam tape

- Adhesive Type

- solvent adhesive

- Color

- Blue and Red

- Tape Thickness

- 0.3-12 Millimeter (mm)

- Use

- Masking

Cloth tapes Trade Information

- Minimum Order Quantity

- 100 Rolls

- Supply Ability

- 1000 Rolls Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About Cloth tapes

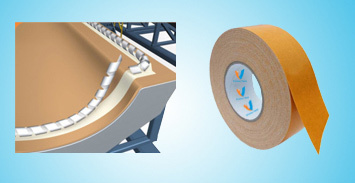

Pressure sensitive tape coated with adhesive on both sides. It is designed to stick two surfaces together, often in a way which is not visible in the end product.

This allows for neater looks and better craftsmanship.

Double-sided tape is created by applying a thin adhesive layer to each side of a carrier material. For example, double-sided tissue tape, an easy-to-rip double-sided tape, is created by applying adhesive to two sides of tissue paper, which is then wound with a siliconed paper to avoid it sticking to itself.

| Backing | PVC Filim |

| Temperature | 0.180 mm |

| Adhesive | Acrylic |

| Features | U.V. Resistance High Tack High Bonding |

| Applications | Mirror Mounting |

Premium Quality Acrylic Foam Tape

Manufactured using premium acrylic foam, our cloth tapes are engineered for longevity and strength. The single-sided adhesive maximizes adherence, while the high-performance solvent adhesive effectively resists lifting and peeling. These tapes are suitable for demanding masking operations, offering durability even during rigorous use.

Vibrant Color Options and Versatility

Available in striking blue and red, the tapes are easy to identify during projects and help prevent masking errors. The variety in tape thickness-from 0.3 mm up to 12 mm-caters to different coverage needs, making them adaptable for a range of surfaces and conditions.

Exporter and Manufacturer from India

As a trusted Indian exporter and manufacturer, we ensure each batch adheres to strict quality standards. Our production process involves advanced machinery and skilled craftsmanship to deliver consistency and reliability with each order, suited for both domestic and international markets.

FAQ's of Cloth tapes:

Q: How should I apply the single-sided acrylic foam cloth tape for masking purposes?

A: Ensure the target surface is clean and dry before application. Unroll the tape and place it evenly along the area to be masked, pressing firmly to achieve optimal adhesion. After the masking process is complete, peel off the tape slowly to avoid leaving residue.Q: What makes this acrylic foam tape suitable for masking applications?

A: The tape is manufactured with a high-quality acrylic foam base and a strong solvent adhesive, ensuring solid adhesion and clean removal. Its flexible construction allows it to conform to irregular surfaces, making it especially effective for masking tasks during painting or surface protection.Q: When is the ideal time to use these tapes in a project?

A: These tapes should be applied during the preparation or masking phase, prior to painting or any finishing process. Their reliable adhesion ensures surfaces remain protected throughout application and can be removed cleanly once the job is finished.Q: Where can these blue and red cloth tapes be used?

A: They are suitable for use in construction, automotive, and general industrial projects, as well as in workshops or DIY environments. Their vibrant colors enable easy identification, making them practical for color-coded masking and demarcation.Q: What process is involved in manufacturing these tapes?

A: The tapes are produced by combining high-grade acrylic foam with a strong solvent adhesive, then coating one side of the cloth material. The rolls are precisely cut into the desired width and length and quality-checked before packaging for export or supply.Q: What are the advantages of using these single-sided cloth tapes compared to others?

A: Benefits include excellent adhesion, versatility in thickness, easy detectability due to color, and residue-free removal. Their robust solvent adhesive works efficiently on diverse surfaces, supporting precise masking while reducing post-job cleaning.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Foam Tapes Category

Polyster tapes

Minimum Order Quantity : 100 Rolls

Tape Thickness : 0.22 Millimeter (mm)

Color : Blue and Red

Adhesive Side : Single Side

Material : acrylic foam tape

Use : Masking

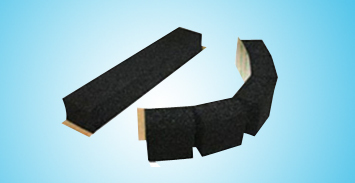

Foam tape die cuts

Minimum Order Quantity : 100 Rolls

Tape Thickness : 0.56 Millimeter (mm)

Color : Blue and Red

Adhesive Side : Double side

Material : acrylic foam tape

Use : Masking

Speciality foam tapes

Minimum Order Quantity : 100 Rolls

Tape Thickness : 0.36 Millimeter (mm)

Color : Blue and Red

Adhesive Side : Double side

Material : acrylic foam tape

Use : Masking

PVC tapes

Minimum Order Quantity : 100 Rolls

Tape Thickness : 0.6321 Millimeter (mm)

Color : Blue and Red

Adhesive Side : Double side

Material : acrylic foam tape

Use : Masking

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS