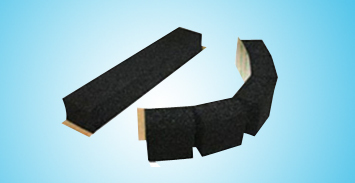

Foam tape die cuts

Foam tape die cuts Specification

- Length

- 50-60 Meter (m)

- Shelf Life

- 6 Months

- Adhesive Side

- Double side

- Material

- acrylic foam tape

- Adhesive Type

- solvent adhesive

- Color

- Blue and Red

- Tape Thickness

- 0.5-6 Millimeter (mm)

- Use

- Masking

Foam tape die cuts Trade Information

- Minimum Order Quantity

- 100 Rolls

- Supply Ability

- 1000 Rolls Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About Foam tape die cuts

Pressure-sensitive tapes and foams with adhesive are pre-cut into desired matrix as for the customer requirements for convience in operations and easy workability.

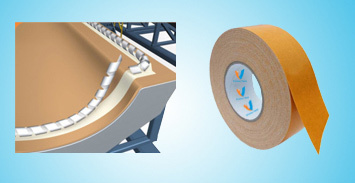

| Backing | PU Foams |

| Density | As per request |

| Adhesive | Acrylic |

| Features | Uniform Cell Structure Available in various Colours |

| Applications | Seailing application in Refrigeration NVH Application in Automotive |

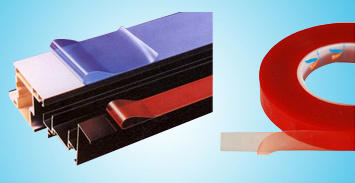

Superior Double-Sided Adhesive Performance

Engineered for reliable masking, our foam tape die cuts utilize a high-strength double-sided solvent adhesive. This ensures secure bonding between surfaces, whether used for assembly, insulation, or protection. The product's acrylic foam base offers excellent durability and flexibility, making it adaptable to various surfaces and applications.

Versatile Applications and Easy Handling

Our die-cut foam tapes are suitable for a wide range of industries, from automotive to construction. Available in blue and red for easy identification, they can be custom-shaped for specific projects. With lengths of 50-60 meters and thicknesses from 0.5 to 6 mm, these tapes streamline processes and save time during both installation and removal.

FAQ's of Foam tape die cuts:

Q: How are Foam Tape Die Cuts with double-sided adhesive typically used?

A: These foam tape die cuts are mainly used for masking purposes, as well as mounting, spacing, and cushioning in various industries. Their double-sided adhesive enables strong bonding between different surfaces, making them suitable for both temporary and permanent applications.Q: What material and adhesive type are used in these die-cut foam tapes?

A: The die cuts are crafted from durable acrylic foam tape and utilize a high-quality solvent adhesive on both sides, ensuring strong adhesion and reliable performance on a variety of substrates.Q: When should these foam tape die cuts be replaced or used by?

A: For optimal performance, it is recommended to use the foam tape die cuts within their 6-month shelf life from the date of manufacture, as adhesive properties may diminish over time.Q: Where can these foam tape die cuts be applied?

A: These tapes are suitable for use on a range of surfaces, including metal, plastic, glass, and painted areas, and are commonly used in automotive, electronics, and construction industries.Q: What is the process for applying these foam tape die cuts?

A: To apply, simply peel off the liner from one side, adhere the tape to the chosen surface, then remove the second liner and press the other surface onto the exposed adhesive. Ensure surfaces are clean and dry for best results.Q: What are the benefits of using double-sided foam tape die cuts?

A: They offer quick, clean, and efficient bonding, reduce the need for mechanical fasteners, and provide excellent vibration damping and insulation, all while being easy to handle and remove when necessary.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Foam Tapes Category

Polyster tapes

Minimum Order Quantity : 100 Rolls

Color : Blue and Red

Material : acrylic foam tape

Adhesive Type : solvent adhesive

Adhesive Side : Single Side

Use : Masking

Cloth tapes

Minimum Order Quantity : 100 Rolls

Color : Blue and Red

Material : acrylic foam tape

Adhesive Type : solvent adhesive

Adhesive Side : Single Side

Use : Masking

PVC tapes

Minimum Order Quantity : 100 Rolls

Color : Blue and Red

Material : acrylic foam tape

Adhesive Type : solvent adhesive

Adhesive Side : Double side

Use : Masking

Double sided tissue tapes

Minimum Order Quantity : 100 Rolls

Color : Blue and Red

Material : acrylic foam tape

Adhesive Type : solvent adhesive

Adhesive Side : Double side

Use : Masking

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS