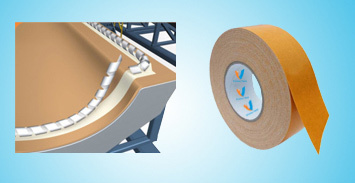

Double sided tissue tapes

Double sided tissue tapes Specification

- Length

- 50-60 Meter (m)

- Shelf Life

- 12 Months

- Adhesive Side

- Double side

- Material

- acrylic foam tape

- Adhesive Type

- solvent adhesive

- Color

- Blue and Red

- Tape Thickness

- 0.3-2 Millimeter (mm)

- Use

- Masking

Double sided tissue tapes Trade Information

- Minimum Order Quantity

- 100 Rolls

- Supply Ability

- 1000 Rolls Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About Double sided tissue tapes

Pressure sensitive tape coated with adhesive on both sides. It is designed to stick two surfaces together, often in a way which is not visible in the end product.

This allows for neater looks and better craftsmanship.

Double-sided tape is created by applying a thin adhesive layer to each side of a carrier material. For example, double-sided tissue tape, an easy-to-rip double-sided tape, is created by applying adhesive to two sides of tissue paper, which is then wound with a siliconed paper to avoid it sticking to itself.

| Backing | Tissue |

| Thickness | 0.05 mm to 0.10 mm |

| Adhesive | Acrylic / Hot Melt / Solvent |

| Features | High Adhesion Easy Die Cut Ablility |

| Applications | Foam Lamination Facias / Stickering Application |

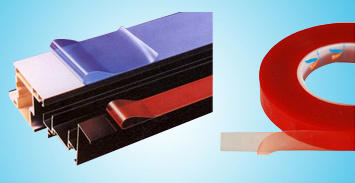

Superior Double Sided Adhesion

Experience robust adhesion on both sides thanks to the solvent adhesive technology employed in these acrylic foam tapes. Suitable for diverse surfaces, the tapes ensure a long-lasting bond, making them ideal for masking as well as general-purpose applications across multiple industries.

Versatility Across Applications

With thickness choices between 0.3 and 2 mm and available in striking blue and red colors, our tapes offer great flexibility. You can rely on their performance for both lightweight and heavy-duty tasks, from crafting and automotive masking to packaging and assembly lines.

FAQ's of Double sided tissue tapes:

Q: How should double sided tissue tapes be stored to maximize their 12-month shelf life?

A: To preserve the tapes' effectiveness for the full 12 months, keep them in a cool, dry environment away from direct sunlight and excessive heat. Avoid areas with high humidity to maintain the glue's integrity.Q: What materials can these acrylic foam double sided tapes adhere to effectively?

A: These tapes are designed to bond securely with a range of materials, including paper, plastics, glass, metals, and painted surfaces, making them versatile for multiple industries.Q: When is it best to use double sided tissue tape over single sided alternatives?

A: Double sided tissue tape is ideal when you need a clean, concealed bond between two surfaces, especially in masking, mounting, or splicing applications where strong yet unobtrusive adhesion is required.Q: Where can this tape be used in manufacturing or exporting operations?

A: Our double sided tissue tapes are widely used in automotive, textile, electronics, and packaging sectors for tasks such as component assembly, temporary holding, and export packaging.Q: What is the typical process for applying this tape for optimal results?

A: Ensure the surfaces are clean and dry. Apply the tape evenly and firmly onto the first surface, peel off the liner, then press the other surface onto the exposed adhesive for a strong bond.Q: What usage benefits does a tape thickness range of 0.3-2 mm provide?

A: The diverse thickness options accommodate both delicate and heavy-duty jobs. Thinner tapes suit fine or precision work, while thicker variants excel at tasks requiring substantial load-bearing capacity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Foam Tapes Category

PVC tapes

Minimum Order Quantity : 100 Rolls

Material : acrylic foam tape

Use : Masking

Adhesive Side : Double side

Tape Thickness : 0.6321 Millimeter (mm)

Shelf Life : 12 Months

Acrylic foam tapes

Minimum Order Quantity : 100 Rolls

Material : acrylic foam tape

Use : Masking

Adhesive Side : Single Side

Tape Thickness : 0.36 Millimeter (mm)

Shelf Life : 6 Months

Cloth tapes

Minimum Order Quantity : 100 Rolls

Material : acrylic foam tape

Use : Masking

Adhesive Side : Single Side

Tape Thickness : 0.312 Millimeter (mm)

Shelf Life : 12 Months

Polyster tapes

Minimum Order Quantity : 100 Rolls

Material : acrylic foam tape

Use : Masking

Adhesive Side : Single Side

Tape Thickness : 0.22 Millimeter (mm)

Shelf Life : 12 Months

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS