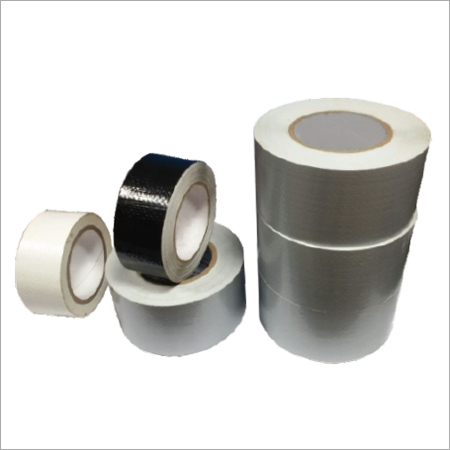

Reinforced tapes

Reinforced tapes Trade Information

- Minimum Order Quantity

- 100 Rolls

- Supply Ability

- 1000 Rolls Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About Reinforced tapes

Pressure Sensitive Tape made of a Films, Fabrics, and coated with suitable adhesive. It is used mainly in packing and protection. suitable tapes are recommended basing on the packing requirements and the protection of surface requirements.

For Protection tapes, the adhesive is the key element to its usefulness, as it allows the tape to be easily removed without leaving residue or damaging the surface to which it is applied.

For packaging Tapes, the carrier is the key element to its usefulness, as it allows the tape to take the weight and the conditions which the package moves in transit.

| Backing | Paper reinforced with Fibre Glass |

| Adhesive | Water base |

| Features | High tensile Strength |

| Applications | Heavy duty packing Preferred export packing |

Exceptional Adhesion and Strength

Engineered with double-sided solvent adhesive, our reinforced tapes provide a steadfast bond on various surfaces. Whether you are involved in automotive, electronics, or general assembly, these tapes guarantee consistent results and stability throughout their intended shelf life, making them a reliable choice for critical applications.

Versatile Usage and Application

These tapes are perfectly suited for masking, mounting, splicing, and other bonding tasks. The combination of acrylic foam and reinforced design ensures longevity and adaptability in diverse operational settings, from workshops to construction sites. Their vibrant blue and red colors facilitate easy identification and enhance workflow efficiency.

FAQ's of Reinforced tapes:

Q: How should reinforced acrylic foam tapes be applied for optimal adhesion?

A: For the best results, ensure that the surfaces are clean and dry before applying the tape. Firmly press the double-sided solvent adhesive tape onto the area, then remove the liner and adhere the other surface. Steady, even pressure increases bonding strength.Q: What are the main benefits of using these tapes for masking and bonding purposes?

A: These reinforced tapes provide exceptional strength and durability due to their acrylic foam base, supporting reliable and long-lasting bonds. The solvent adhesive enhances the tape's grip, making it suitable for heavy-duty masking and mounting tasks across various industries.Q: When is it necessary to replace stored rolls of tape?

A: It is recommended to use the tapes within their 12-month shelf life to ensure optimum performance. After this period, the adhesive's effectiveness may decline, especially if stored in unfavorable conditions.Q: Where are these reinforced tapes manufactured and available for export?

A: These tapes are manufactured in India and are available for export worldwide. As a reliable exporter and manufacturer, we ensure that all products meet international quality standards.Q: What process is used to manufacture these reinforced acrylic foam tapes?

A: The tapes are produced by layering high-quality acrylic foam and applying a double-sided solvent adhesive. This process results in a reinforced structure with superior adhesive strength and reliable performance for various applications.Q: How can these tapes be used in industrial or commercial settings?

A: They are ideal for tasks such as masking before painting, mounting objects, splicing materials, or securing panels. The tape's double-sided adhesive offers versatility, enabling use in assembly lines, automotive repairs, and construction projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging & Protection Tapes Category

HDPE Fabric Tape-PP Fabric Tape

Minimum Order Quantity : 100 Rolls

Color : Blue and Red

Adhesive Side : Double side

Adhesive Type : solvent adhesive

Shelf Life : 12 Months

Use : Masking

PE protection tapes

Minimum Order Quantity : 100 Rolls

Color : Blue and Red

Adhesive Side : Double side

Adhesive Type : solvent adhesive

Shelf Life : 12 Months

Use : Masking

Surface Protection

Minimum Order Quantity : 100 Rolls

Color : Blue and Red

Adhesive Side : Double side

Adhesive Type : solvent adhesive

Shelf Life : 12 Months

Use : Masking

PVC Insulation

Minimum Order Quantity : 100 Rolls

Color : Blue and Red

Adhesive Side : Double side

Adhesive Type : solvent adhesive

Shelf Life : 12 Months

Use : Masking

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS